Frequently asked questions and solutions for Three-phase Thyristor Controller

What common problems may you encounter when using the Three-phase Thyristor Controller?

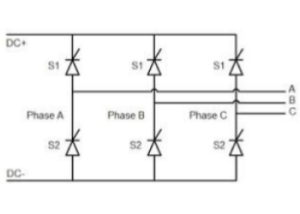

A three-phase Thyristor Controller is a standard electronic device used to control the on and off of AC power. However, you may encounter various problems during use, such as failure to start, uneven conduction, overheating, false triggering, operating noise, improper parameter settings, hardware failures, software failures, and cooperation problems with other devices. These problems may affect the regular operation and use of the equipment, so corresponding solutions must be adopted for different issues.

(Three-phase Thyristor Controller)

How do we solve the problems encountered by the Three-phase Thyristor Controller?

- Unable to start: If the Three-phase Thyristor Controller cannot be created, first check the average input power and whether the power connection is correct. In addition, check whether the control signal is standard. If there is a problem with the control signal, such as the signal amplitude being too small or the frequency being incorrect, it may also prevent the controller from starting.

- Unsmooth conduction: If the conduction of the Three-phase Thyristor Controller is not smooth, it may cause current waveform distortion and harmonic interference; this may be caused by inaccurate phase control of the control signal or inappropriate width of the trigger pulse. At this time, you can try to adjust the phase or pulse width of the control signal to improve the conduction characteristics.

- Overheating: If the Three-phase Thyristor Controller overheats, it may be made for by poor heat dissipation or long-term high-load operation of the device. Overheating can cause equipment damage, so steps need to be taken to reduce the temperature of the equipment. Measures that can be taken include enhancing the thermal design of the device or regularly checking its temperature while the machine is running.

- False triggering: In some cases, the Three-phase Thyristor Controller may trigger incorrectly; this may be caused by interference in the control signal or a fault in the device itself. Some measures can be taken to improve the stability of control signals, such as adding signal filters or improving the shielding of signal transmission lines to prevent false triggering.

- Operation noise: A three-phase Thyristor Controller may generate noise during operation; this may be caused by electromagnetic interference or mechanical vibration of the device itself. Some measures can be taken to improve the electromagnetic shielding performance of the equipment or minimize mechanical vibration to reduce noise.

- Maintenance issues: The three-phase Thyristor Controller requires regular maintenance, including cleaning the surface of the equipment and checking whether the wiring is loose, etc. Improper care may result in equipment failure or shortened service life. Therefore, the equipment needs to be inspected and maintained regularly.

- Wrong parameter setting: If the parameter setting is improper, such as the trigger angle setting is too large or too small, it may cause the equipment to work abnormally. You can now refer to the device’s parameter setting guide to set the parameters within the appropriate range.

- Hardware failure: Hardware failure of the Three-phase Thyristor Controller may be caused by quality problems or damage caused during use. For example, thyristors may suffer from short-circuit or open-circuit faults. In this case, the device will need to be sent for repair, or the faulty part will need to be replaced.

- Software failure: If the software of the Three-phase Thyristor Controller fails, it may cause the device not to work correctly; this may be due to design issues in the software itself or damage caused during use. At this point, you can reinstall the software or update it to the latest version.

- Cooperation issues with other equipment: If the Three-phase Thyristor Controller does not work correctly with other equipment, such as mismatching the power supply or motor, it may cause the equipment to function abnormally. Therefore, when selecting and using devices, you must ensure they are compatible.

(Three-phase Thyristor Controller)

What other precautions should be taken when using the Three-phase Thyristor Controller?

You may encounter various problems when using the Three-phase Thyristor Controller, which must be analyzed and solved according to the specific situation. In addition to the solutions mentioned above, you also need to pay attention to the following points:

- Please read the user manual and safety operating procedures in detail before use;

- Equipment should be inspected and maintained regularly during use;

- When encountering a problem, you should first try to eliminate common fault factors, and if you cannot solve it, seek professional help;

- Care should be taken to protect the equipment from damage from harsh environments and human factors;

- After use, turn off the power and clean up the site.

Supplier

PDDN Photoelectron Technology Co., Ltd. is a high-tech enterprise focusing on the manufacturing, R&D and sales of power semiconductor devices. Since its establishment, the company has been committed to providing high-quality, high-performance semiconductor products to customers worldwide to meet the needs of the evolving power electronics industry.

It accepts payment via Credit Card, T/T, West Union, and Paypal. PDDN will ship the goods to customers overseas through FedEx, DHL, by sea, or by air. If you are looking for high-quality PHASE CONTROL THYRISTORS, please send us inquiries; we will be here to help you.